Readers will also learn how to choose the best design solution for any applicationReaders of Hydraulic Fluid Power will benefit fromApproaching hydraulic fluid power concepts from an outside-in perspective emphasizing a problem-solving orientationAbundant numerical examples and end-of-chapter problems designed to aid the reader in learning and retaining the materialA. Over sizing the reservoir by 5 to 15 gallons will offer substantial benefits by allowing the.

Water Free Full Text Optimal Design Of Water Treatment Contact Tanks Html

The paper presents the development of industrial 400 litre hydraulic tank.

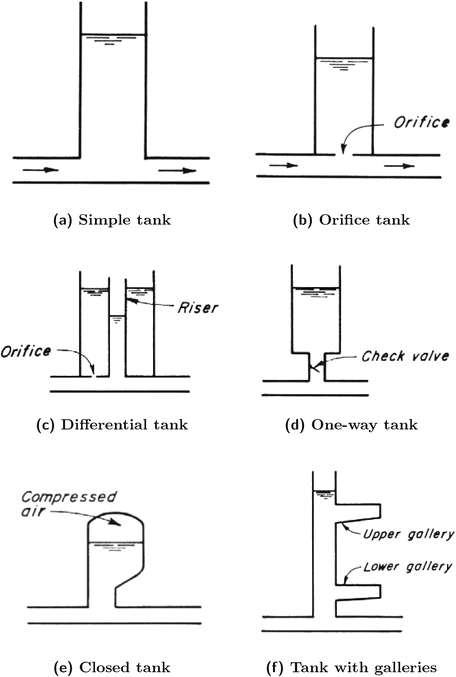

. Water utilities like to operate treatment plants at a relatively constant rate and wells and pumping stations generally work best when pumped at a steady rate. An orifice tank having a riser is called differential tank. Abstract Water distribution storage ensures the reliability of supply maintains pressure equalizes pumping and treatment rates reduces the size of transmission mains and improves operational.

It reduces the water starting time of a hydropower scheme. One of my clients a Rotational Moulding manufacturer Amber Plastics has expertise and a great deal of experience in the field. There are several key considerations in the hydraulic design of water storage tanks.

3370-2009 Part - II. The basic functions of any hydraulic tank are to store and supply fluid. Pump inlet conditions should be a critical design consideration for any hydraulic system.

Each design consideration already discussed plays a part in optimum pump inlet conditions and I should mention a baffle is a key strategy in reservoir construction. Considerations a b and d of the computations in Section 3 apply with the only difference that instead of e and e e or 06 e always l o Equation 424 and D o Equation 425 respectively should be understood. Int J Simulat Model.

3- Differential surge tank. Hydraulic System Design Operation. There are several key considerations in the hydraulic design of water storage tanks.

Design engineers are always pressured to reduce the size of hydraulic reservoirs while equipment operators always appreciate larger reservoirs. Pressure cap ensures that pressure contains in the tank and it also relieves extra pressure. Richer Mix are employed - M20 M30 High Water Tightness have to be provided The bending and tension stress value is kept within the permissible value in order to prevent cracking.

At an absolute minimum the additional analysis of the 1 AEP discharge is required for both the existing and the proposed conditions. The water in the pipeline is thereforeaccelerated or decelerated slowly and the amplitude of the pressure waves in the system is reduced 5. It is best to construct a single compartment for small capacity septic tanks.

This article has been written to fuel the imagination of design engineers working on Hydraulic Tanks. Equalization is the primary purpose for constructing water distribution storage tanks. The important considerations in the design of water tank is as per IS.

Hydraulic Aspects in Designing Aquaculture Systems. 5- Closed surge tank. Stores or provides water.

When designing a hydraulic system clear operational specifications must be identified for the user such as. For example contamination control can be enhanced with one or more return return-suction suction and filling filters. Design of modern hydraulic tank using fluid flow simulation.

Hydraulic system design considerations The most susceptible components in any hydraulic system are the pump motors and cylinders. Never undersize the reservoir. If the top of the tank is closed and there is.

Large flow cross-sections for suction and return ports ensure a compact installation height. The location and inlet requirements are essential determining factors of the pump. Rotational Moulding - Hydraulic Tank Design.

1 The permissible stress in steel is as per Table4. In a one way surge tank the liquid flows from the tank into the pipeline only when the pressure in the pipeline drops below the liquid level in the surge tank. 4- One- way surge tank.

An overall hydraulic performance curve for the designed culvert indicates headwater and outlet velocity characteristics for the entire range of discharges. The HIT does much more. The excess reserve oil in a hydraulic system is to dissipate heat and prolong the life of the pump.

Performance and Function Considerations of Hydraulic Tanks. A pressurized or vented reservoir is also to consider when choosing a hydraulic tank. The pressure cap should have overshoot properties and low pressure.

Morning glory vertical section. Reservoirs can also help separate dirt and other particulate from the oil as the particulate will generally settle to the bottom of the tank. In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants.

1 The permissible stress in steel is as per Table4. Cooling considerations The reservoir often just called the tank also provides significant surface area for cooling of the hydraulic fluid. Numerous decisions must be made in designing a storage tank including size location type and expected operation.

In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is preferred by some whereas others use the word reservoir to describe only ground-level and buried tanks. Here are some important points to consider in designing and using hydraulic systems. Station Layout Considerations Provide sufficient work space between pumps Use largest pump and motor dimensions now or future Allow for expansion Think through process of installingremoving pumps and valves Size crane and openings for heaviest largest single item in the station Ensure crane can reach everything it needs to lift.

Water distribution storage ensures the reliability of supply maintains pressure equalizes pumping and treatment rates reduces the size of transmission mains and improves operational flexibility and efficiency. This chapter focuses on the hydraulic aspects of design as opposed to structural corrosion safety contamination or instrumentation aspects. Improves the regulating characteristics of a hydraulic turbine because.

In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants. There are several key considerations in the hydraulic. Fluid entering the pump should be clean cool and free from aeration.

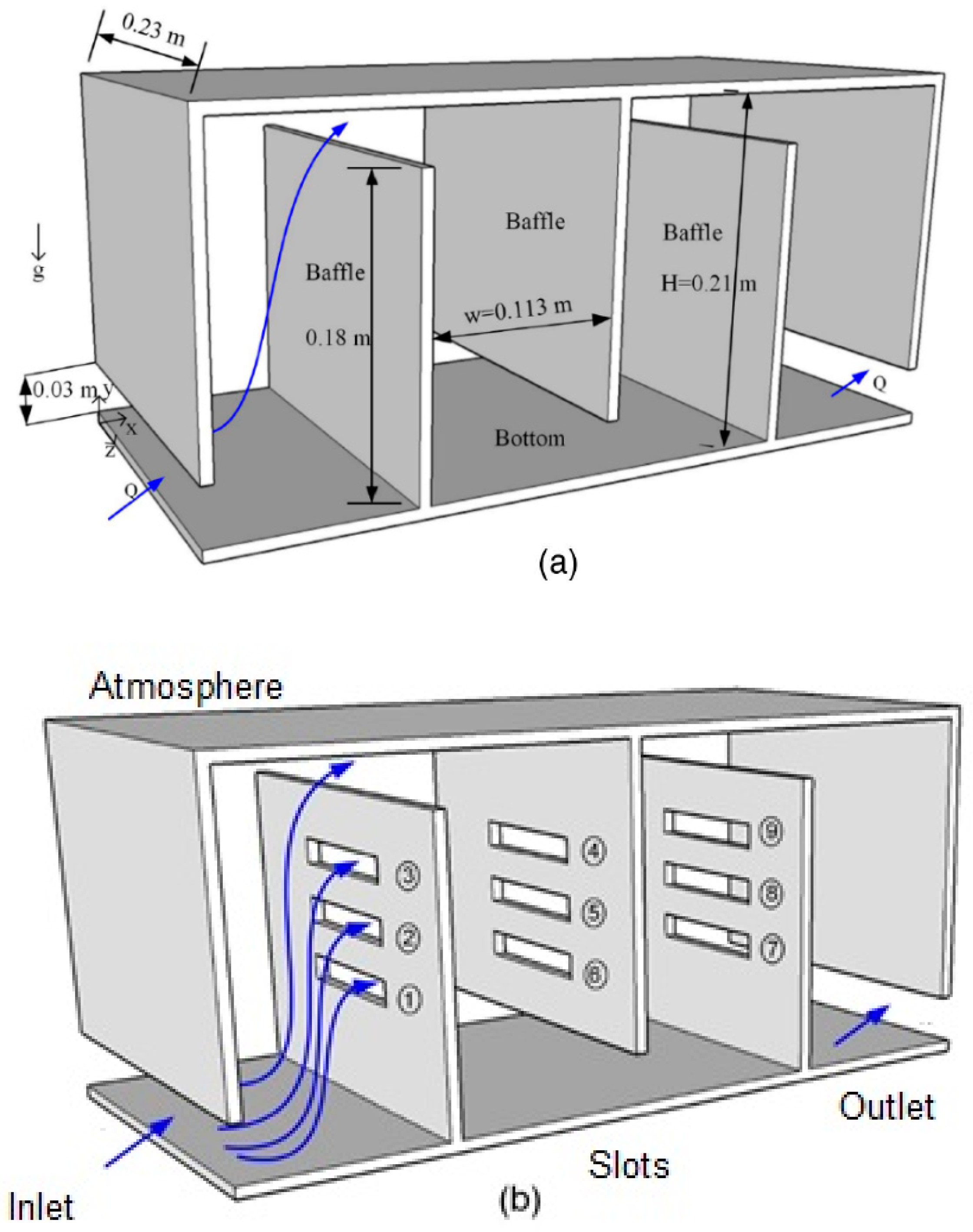

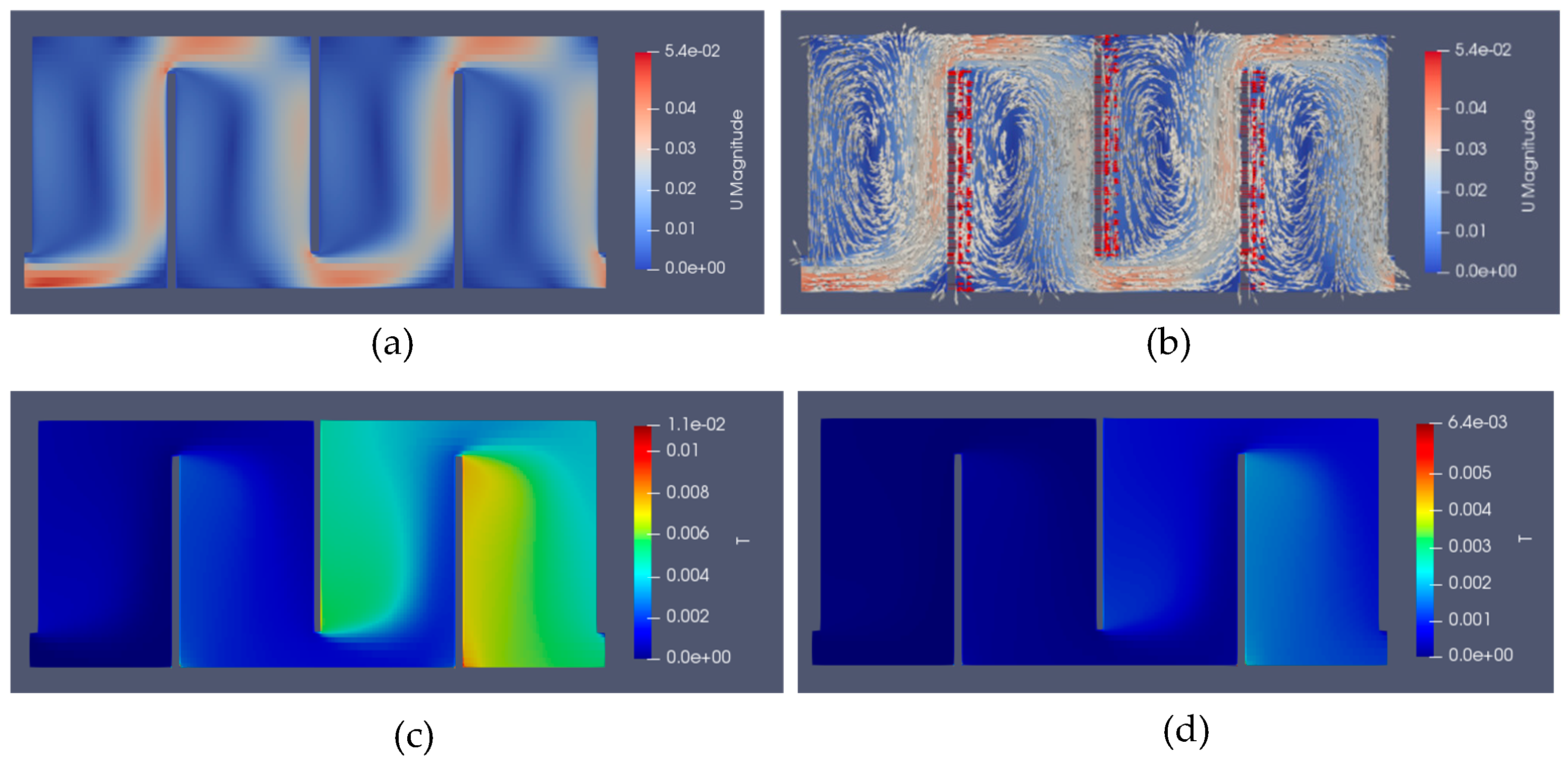

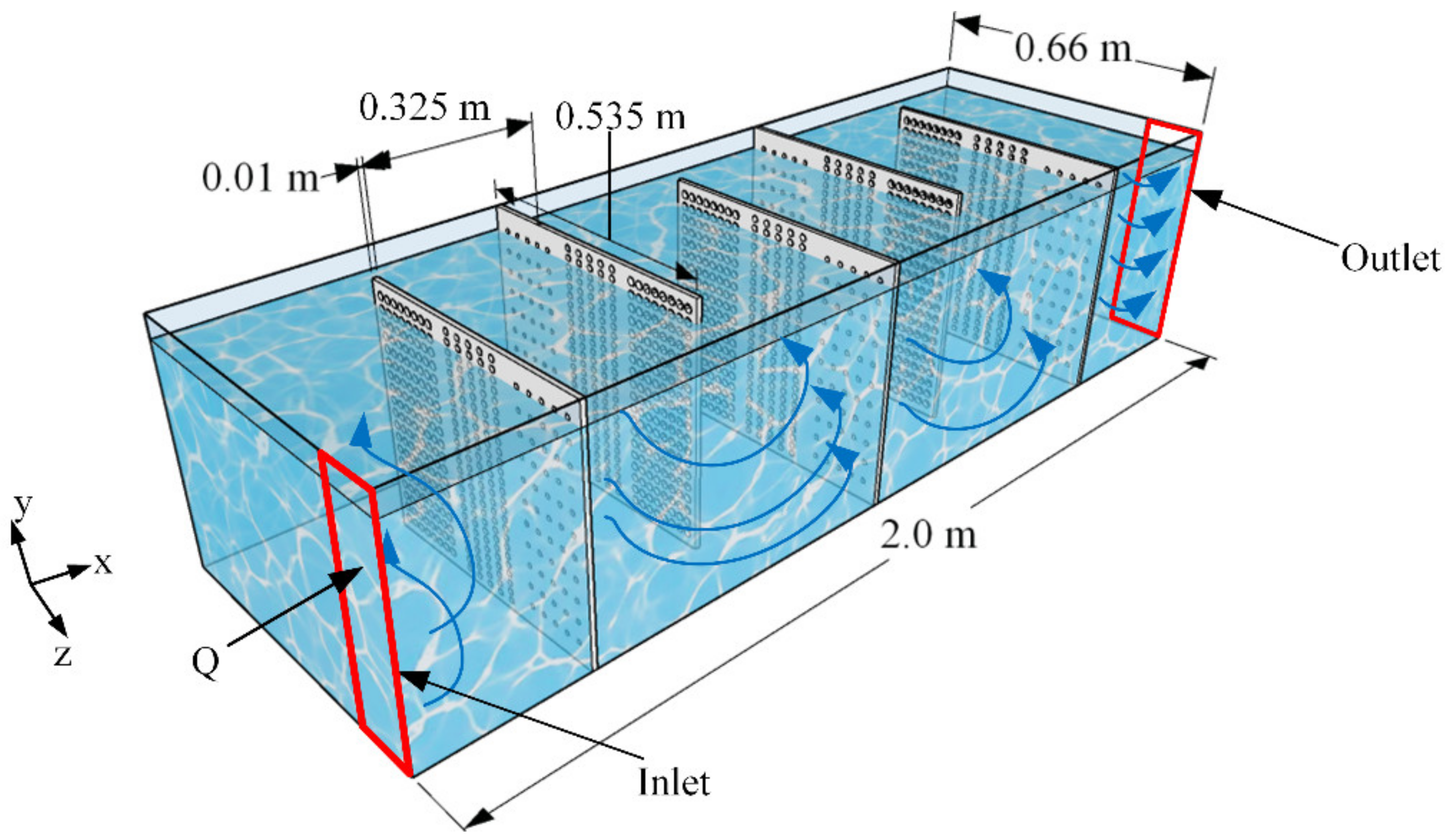

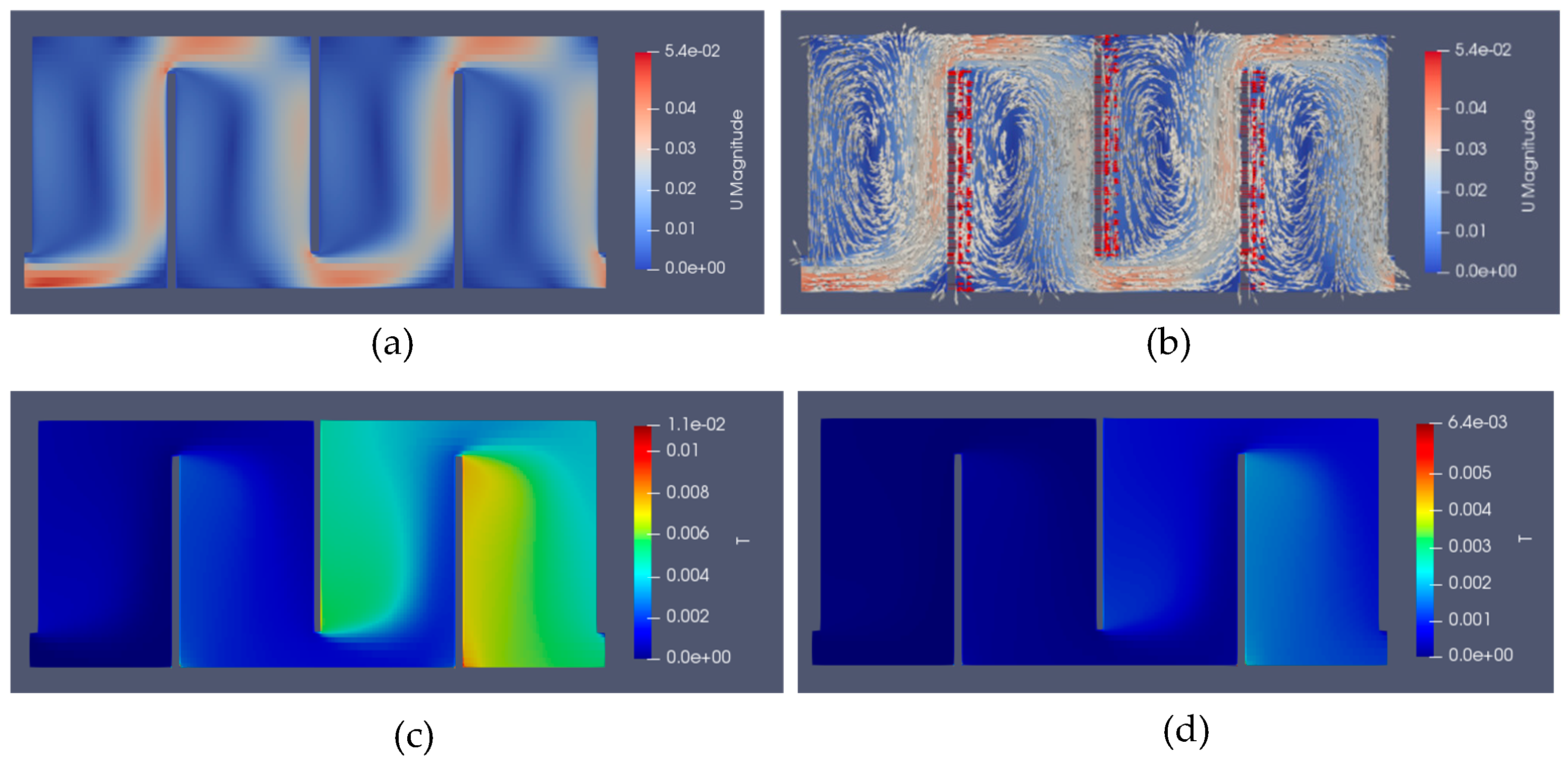

Water Free Full Text A Perforated Baffle Design To Improve Mixing In Contact Tanks Html

Water Tanks Roof Water Tank Overhead Water Tank Design For Home Tank Stand

Water Free Full Text Optimal Design Of Water Treatment Contact Tanks Html

Schematic View Of Full Scale Chlorine Contact Tank Cct With Dimensions Download Scientific Diagram

Hydraulic Reservoir Design Considerations

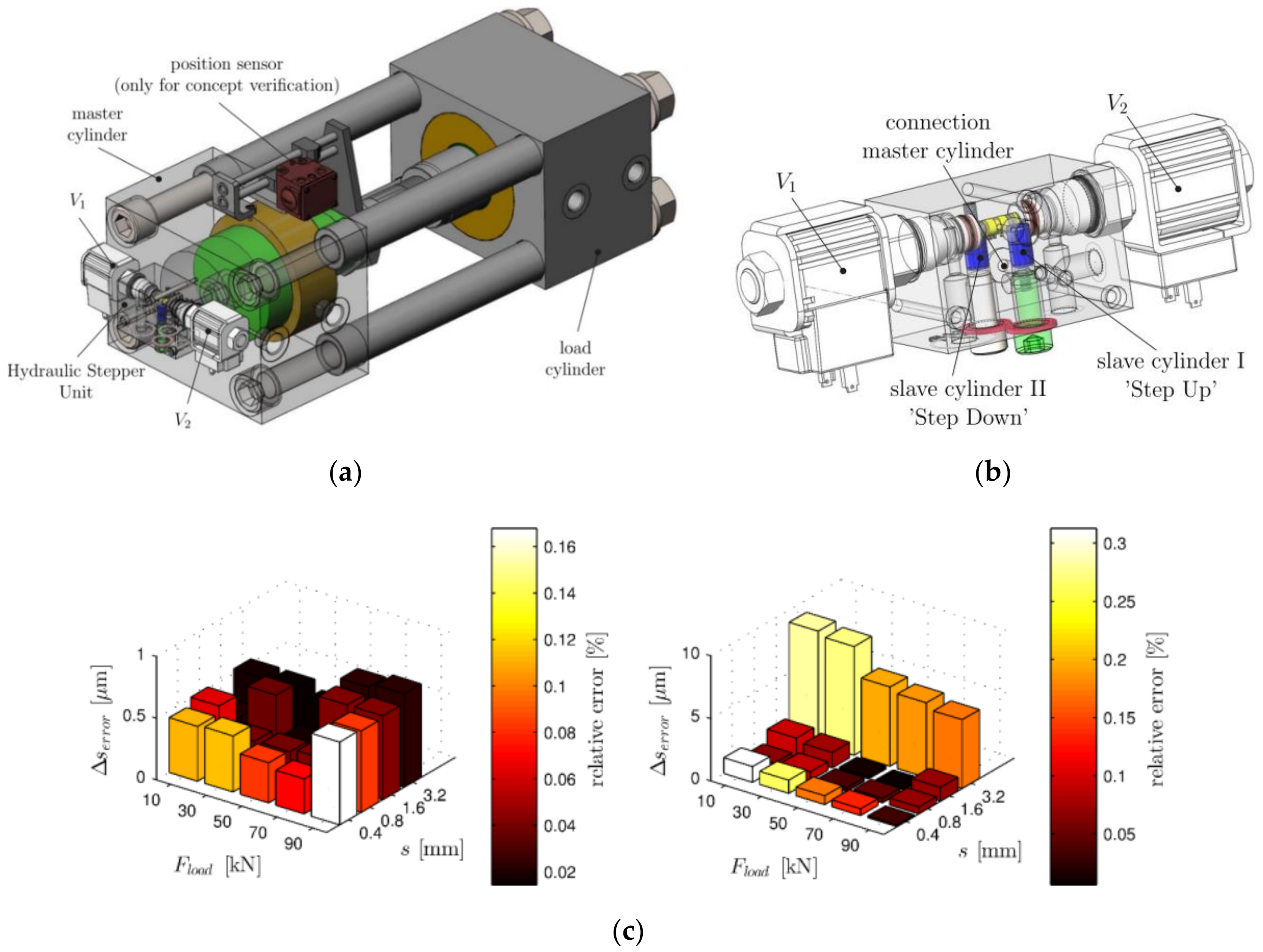

Applied Sciences Free Full Text Review And Development Trend Of Digital Hydraulic Technology Html

0 comments

Post a Comment